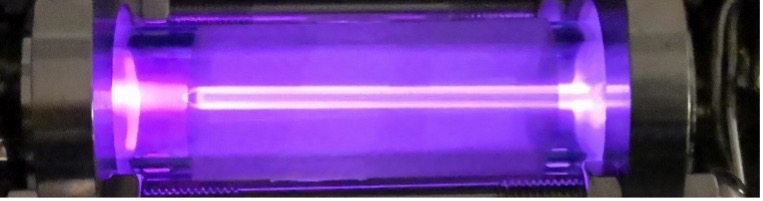

PNE has successfully developed a novel Low-temperature Plasma-assisted Separation Process (LPAS™). This process enables sorting, purification, and repair of cathode materials from aged lithium-ion batteries and adds new functionality to improve cathode materials’ performance. The success of our technology enables the repair of cathode and anode materials without completely breaking down the chemical compounds, which significantly reduces energy and chemical consumption compared to current industrial processes. The direct repair of cathode materials using PNE technology will increase the commercial viability of LIBs and reduce battery cost, thus accelerating the electrification of transportation and large-scale energy storage for renewable energy in the near future. Moreover, LPAS™ technology is transformative. It can create a new LIBs cathode material manufacturing process from recycled batteries and establish U.S. leadership in the manufacturing of LIBs. The LPAS™ approach offers systematic advantages in costs, energy efficiency, and environmental protection by reusing, recycling, and reproducing LIBs within an optimized system.

Copyright © 2023, Princeton NuEnergy Inc. All Rights Reserved.