NJIT Alum’s Startup Earns National Acclaim for Li-Ion Battery Recycling Technology

For all the convenience of our electronic devices, one inconvenient truth is that waste from our discarded tech is piling up — global e-waste could reach a whopping 74 million metric tons in 2030. NJIT alum Chao Yan’s new greentech startup, Princeton NuEnergy, is receiving national acclaim for their solution to a key aspect of the environmental dilemma — what happens to our smartphone and laptop batteries once we’re done with them?

The Princeton University-based startup, founded in 2019, was awarded the 2021 U.S. National Grand Prize by CleanTech Open, the world’s largest clean technology accelerator program, for its novel recycling strategies on lithium-ion batteries found in everything from iPhones to Tesla.

Yan’s team beat out more than 120 startups that entered the annual pitch competition, which launched in 2006 to “find, fund and foster the most promising cleantech startups on the planet.” As grand-prize winners, Princeton NuEnergy received a $50,000 SAFE note as well as consulting and legal support from CleanTech Open to back the company’s ambitious plans this year.

“Even though we were very confident in our technology going into the CleanTech Open, we never expected to be the grand-prize winner, so it’s very exciting, and we are certainly receiving a lot more attention since the award will only help us grow,” said Yan, who received his Ph.D. in chemistry from the Department of Chemistry and Environmental Sciences in NJIT’s College of Science and Liberal Arts in 2017. “I think our solution comes at a critical time and is ready to scale up now … perhaps that factored in the judges’ decision.”

A Solution at a Critical Time

In the U.S., only about 5% of lithium-ion batteries are currently recycled, but by 2030 that number will need to improve dramatically. Along with increasing battery waste from personal electronics, our cars may also soon contribute to the problem, as electric vehicle (EV) sales are expected to jump from 1.7 million to 26 million by the end of the decade. Overall, some experts estimate 80 metric tons of lithium-ion batteries will need to be recycled in the U.S. in 2030 alone.

The problem, Yan says, is that unlike more easily disposable batteries such as alkaline batteries, the complex design of li-ion batteries means the current cost of recycling them can often outstrip the value of the recovered battery components.

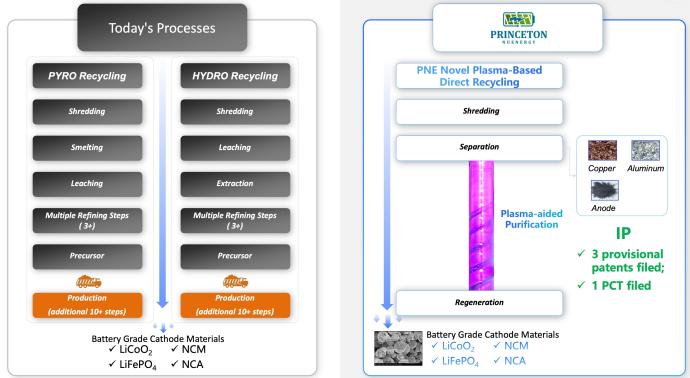

“Most li-ion battery recycling methods right now involve acid leaching, which is costive, pollution-intensive and time-consuming,” explained Yan. “The leaching process involved is normally slow and consumes acids, producing a large quantity of acidic wastewater containing toxic metal ions that is very challenging to handle. The purification of the ions is difficult, sometimes requiring organic solvents to perform the job.”

Princeton NuEnergy’s solution instead involves a novel plasma-based purification technology, which Yan says he first began studying at NJIT under his faculty-mentor, Chemistry Professor Lev Krasnoperov. With the company’s improved process, valuable battery materials such as cathode and anode can be recycled, restored and reused with a fraction of the steps typically involved.

Credit: Princeton NuEnergy

“With our approach, we are able to more simply separate valuable material like the cathode and use plasma to clean the material, minimizing impurities in the recycling step,” said Yan. “The deep cleaning in our system guarantees the high quality of the final products … we can produce the battery grade materials just like virgin materials.

“Our approach reduces the chemical use and waste production, and generates a high quality of battery materials with lower costs than current industrial process.”

PNE’s solution is promising. Yan says his company’s technology requires less than two days to recycle li-ion battery components while also reducing CO2 emissions by up to 80%, water use by 70%, and overall cost by 50% compared to current industrial recycling processes.

And that’s not all.

His company’s technology has attracted much attention this year, including receiving backing from Princeton’s IP accelerator program, grant funding from the U.S. Department of Energy, and a new partnership with the Fortune Global 500 company Wistron Corp. on a “Lithium-Ion Battery and Kickoff Pilot Project”.

According to Yan, the latter may perhaps be the most significant because it will soon give his company something generally lacking in the li-ion supply chain picture — recycling infrastructure.

“We aren’t just a startup with an idea. We are transferring our technology into a real industrial project that will allow us to recycle and repurpose lithium-ion batteries at scale,” said Yan. “Our pilot line with Wistron GreenTech is being built right now in Dallas and is set for completion in the first quarter of 2022 … This will give us a platform to begin forming other key partnerships, with EV companies for instance.”

“Our mission is to have a li-ion battery recycling capacity of 20,000 tons by 2024, and by 2028, we plan to have more than a 100,000 tons capacity,” said Yan.